John Cockerill Defense has 3 production sites located in France and Belgium which allow us to respond efficiently to all types of requests. It creates in particulara capacity for rapid and efficient ramping up of the production line which is the fruit of John Cockerill’s two hundred years of experience.

Facilities

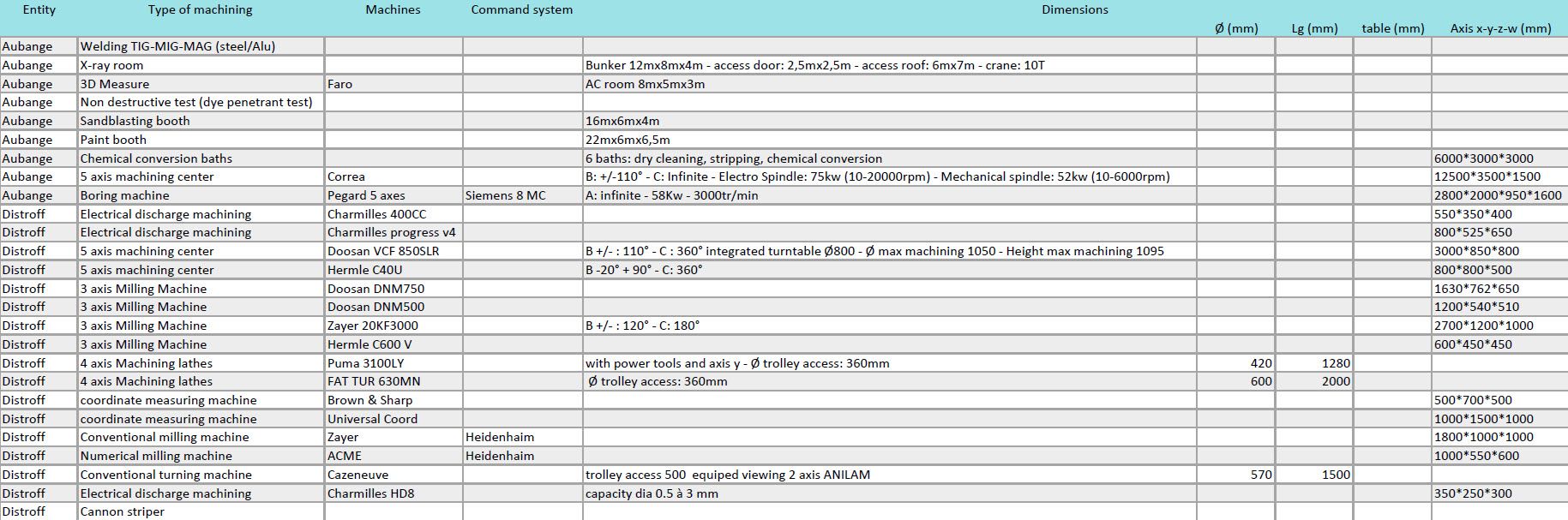

- 3 functional sites with modern, high-performance equipment:

– Aubange: 9000m².

– Distroff : 3360m²

– Guenange : 3500m². - 1 proceduresoffice (mechanics, welding & machining)

- 1 design office (engineering & design)

- IT tools :

– Catia V6 (3DEXPERIENCE DASSAULT SYSTEMES)

– Solidworks SP 5.0

– TopSolid - Lifting equipment: < 20T

- Qualifications : John Cockerill Defense has all the qualifications that guarantee quality work throughout the product life cycle. It also has a strong commitment to the safety and development of its teams.

– COFREND level 2 personnel

– EN 9100: 2016 – Industry

– ISO 14001: 2015 – Environment

– ISO 3834 : 2018 – Welding

– Weapon storage agreement

– TACOM / MIL-STD-3057 (American code) – Aluminium welding

– ISO 15614 /15613 – Aluminium, steel and shielding steel welding - Production facilities : with a long experience in the defence sector, John Cockerill Defense has equipped itself with production means